Valley Design Corp.

Valley Design is an AS9100D/ISO 9001:2015 certified manufacturer of substrates, windows, wafers, precision shims and spacers, flat optics, and complex machined components including domes. Since 1975 we have been recognized as an industry leader in advanced materials processing as providers of precision lapping and polishing services, 4 & 5 axis CNC machining, dicing, backgrinding, ultrasonic hole drilling, edge and angle polishing, and other precision machining services. With 35,000 square feet of manufacturing facilities, we operate over 100 single and double sided lapping, polishing and grinding machines up to 64” to handle parts from as small as 0.127 mm square to as large as 1.83 meters (6 feet) in dimension. We also offer production dicing services. Our 4 & 5 axis CNC micromachining capabilities enable us to fabricate complex shapes and machine features such as pockets, cavities, slots, channels, chamfers, through-holes, radii and steps, all with tight tolerances. We also have the capability to machine domes.

Products & Materials

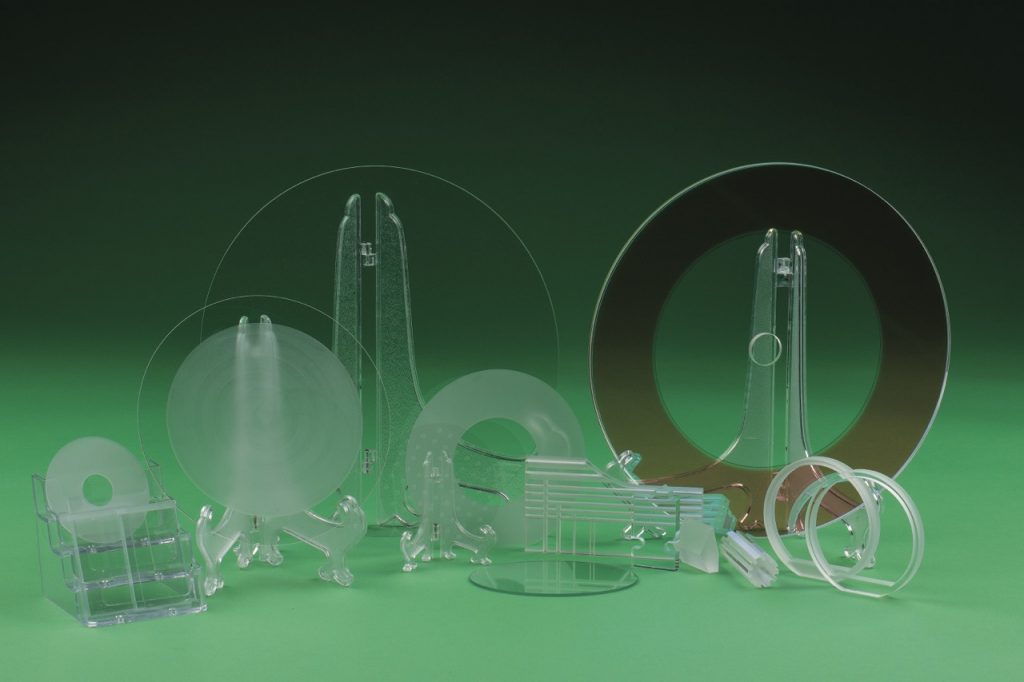

Valley manufactures many different types of standard and custom products, and we process both our own materials and customer supplied parts. To our customers worldwide, we provide substrates, windows, wafers, discs, precision shims and spacers, washers, submounts, color glass filters, prisms, wedges, domes, flat optics, large ceramics up to 450 mm diameter, large metal mirrors, and SEMI standard dummy wafers up to 450 mm diameter. We process a wide variety of optical and semiconductor materials including Fused Silica, Fused Quartz, Glass of all types including Borosilicates, Soda Lime, Optical Glass, Gorilla Glass, Color Filter Glass, Sapphire, 96% Alumina, 99.6% Alumina, Aluminum Nitride, Silicon Carbide, Macor, Silicon, Stainless Steel, Aluminum, Copper, Tungsten, exotic alloys such as Inconel and Hastelloy, Molybdenum, Ferrites and plastics such as Peek and Ultem. We also stock many of these materials and have 1000’s of finished substrates and wafers in inventory.

Special Capabilities

Along with traditional lapping, polishing, dicing and CNC machining, Valley has developed special processing capabilities. We manufacture 300mm dielectrics and insulators for electrostatic chucks and provide ESC chuck refurbishing services. We provide ultra-thin parts, depending on the material and size as thin as 10 microns, ultra-flat (1/10 wave), superpolishing (1 Angstrom), tight tolerances +/- 0.25 microns, parallelism and TTV to 0.1 micron. We work with micron level tolerances, difficult surface finishes, parallelism and flatness specifications, and provide some of the quickest lead times in the industry.

Why Try Valley Design?

- Over 50 years of experience in precision lapping, polishing, dicing, grinding, and 4 & 5 Axis CNC machining of all materials

- Excellent reputation for precision, innovation, quality and customer service

- 35,000 square feet of manufacturing facilities – AS9100D/ISO 9001:2015 certified and ITAR registered.

- Flexibility to work with our customers from prototypes and R&D to

full production - Wide variety of equipment to process all materials from soft PEEK and polyimide to hard Sapphire and ceramics

- Over 100 single and double side Lapping and Polishing machines from 12” – 64” for small to large geometry lapping and polishing to process parts from 0.125mm square up to 48” diameter

- Production dicing capacity: Over 15 programmable DISCO and K&S dicing saws

- 4 & 5 Axis Haas CNC machining: Complex shapes including domes, and features such as through-holes, pockets, corner chamfers, radii, steps, slots, edge chamfers, precision shims, spacers, washers and submounts

- Large in stock inventory of materials including Fused Silica, Glass, 96%/99.6% Alumina and Aluminum Nitride Ceramics, Sapphire and more

- 1000’s of finished substrates and wafers in inventory available for immediate shipment

- Comprehensive process, fixturing, equipment and tooling knowledge

- Advanced R&D and metrology capabilities

- Highly experienced and skilled process technicians – 100’s of years of collective experience

- Worldwide customer base with direct sales representation in Germany and France

- Live customer service assistance available from 8:00AM Eastern Standard Time to 5:00PM Pacific Time (US)