Your Partner for High Precision in Positioning, Automation and Metrology

With the development and production of market-leading solutions in the field of high-precision positioning, micro-automation and metrology, the SmarAct group reliably accompanies their customers in achieving their goals. The broad product portfolio – from single positioning stages to complex parallel kinematics, miniaturized robots, control systems and measurement technology – is completed by automated microassembly solutions. Even the most challenging customer requirements can be met by maximum adaptability and a complete in-house production. SmarAct draws on years of experience and, more importantly, on a very passionate team with unconditional customer focus.

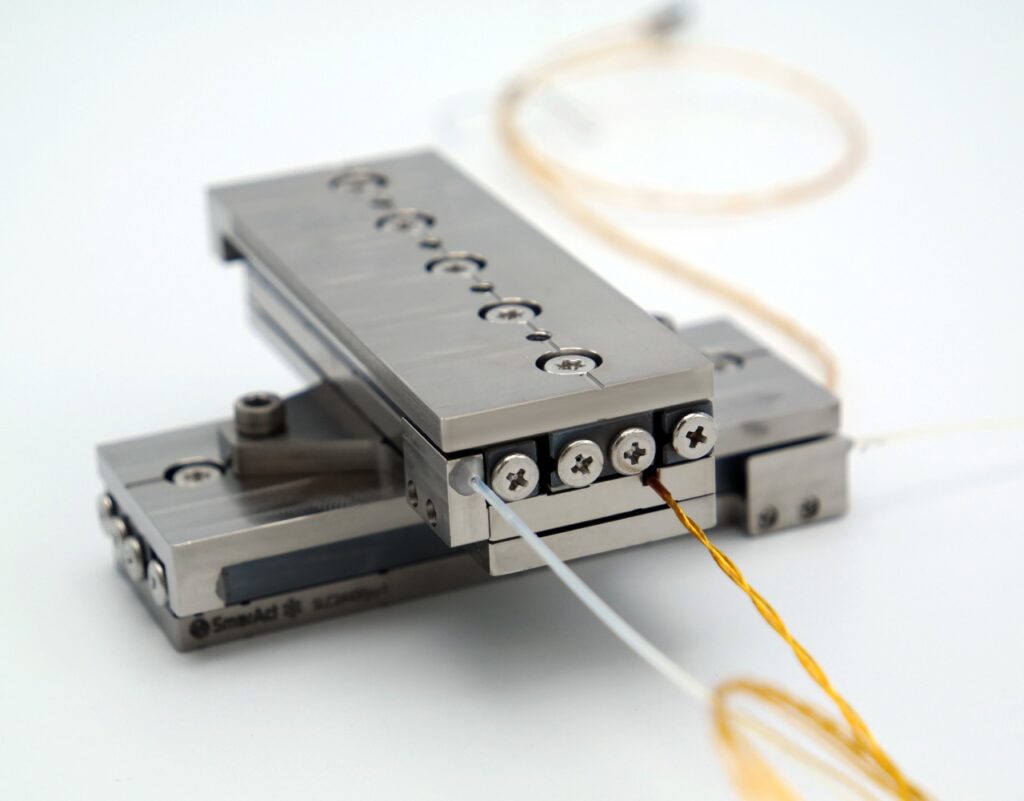

Exchangeable Drive Units

SmarAct Motion’s exchangeable drive units (EDUs) are specifically designed for industrial applications where continuous operation is required. The stick-slip piezo drive is housed in a robust drive unit that you can easily replace yourself. This does not require removing the payload from the stage or the stage itself from the positioning setup. The EDUs allow you to schedule maintenance intervals for piezo actuators and reduce downtime for piezo motor replacement to just a few minutes. The unique and patented drive units are available for CLS series linear stages, CGO goniometer stages, CHS highload stages and long travel CLL stages. Complete positioning systems, from serial multi-axis systems to highly complex parallel kinematics such as the hexapod-like SMARPOD, can also be equipped with SmarAct’s EDUs.

Closed-Loop Cryogenic Stages

For cryogenic applications where highest precision and thermal stability are essential for successful operation, SmarAct Motion has developed cryogenic positioning stages featuring unmatched closed-loop positioning performance with resolutions below 0.5 nm and unidirectional repeatabilities of 5 nm over a 1 mm travel range. This makes the closed-loop cryogenic stages ideally suited, for example, in the field of fundamental research including 2D materials science or for cryogenic applications such as low-temperature quantum technologies. The high-performance stages are specifically designed to meet the most demanding requirements that world-changing technologies like quantum computing induce. Fully non-magnetic versions are available for use in high magnetic fields. To fulfill customers’ individual requirements, completely customized setups are also possible. For the closed-loop cryogenic actuators, SmarAct Motion combines its stick-slip piezo drive stages with SmarAct Metrology’s high-performance PICOSCALE sensor heads, which are based on an all-optical Michelson interferometric design.

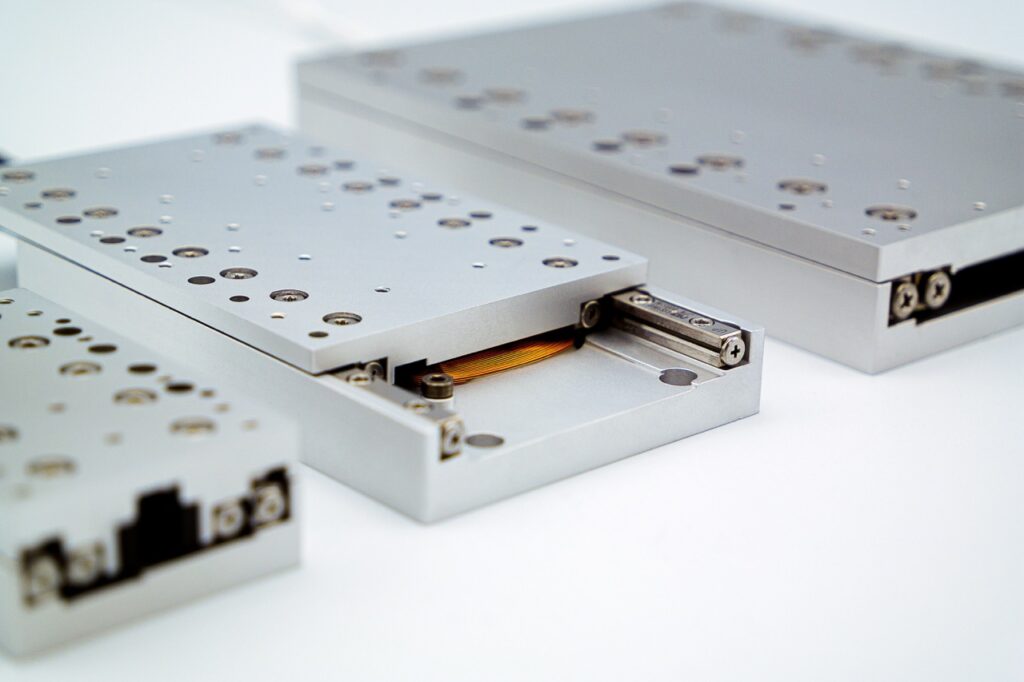

Electromagnetic Direct Drives

The MLS and MLL product series offers electromagnetic linear motors for industrial applications, laboratory automation and compact positioning solutions where high speed, force and nanometer-precise motion must be paired with high durability. The linear positioners feature SmarAct’s non-contact and almost wear-free electromagnetic direct drives, opening up a field of applications where highly dynamic processes require high speed and nanometer accuracy at the same time. The electromagnetic drive enables speeds of up to 1 m/s. In addition, they are extremely durable and virtually maintenance- free. Their compact size ensures seamless integration into existing systems. MLS positioning stages are designed to be intercompatible with SmarAct’s standard size piezo-driven positioning systems. The MLS product series is complemented by standardized mounting elements, base plates and pneumatic support systems for vertical operation to compensate for static or variable payloads. The stages are powered by the reliable MCS2 controller series.

Scanner Stages

For precise scanning applications, SmarAct Motion offers scanner stages with different scan directions based on lever amplified piezo actuators. These stages can easily be combined to form multi-axis scanning systems. Because of the small mass to driving force ratio, scanner stages can realize a highly dynamic motion and due to the actuation principle, a continuous and vibration free motion is possible. The guiding is realized with FEM-optimized flexures, which are free of friction and lead to motion with very high repeatability. Integrated position sensing provides closed-loop positioning with nm-resolution.

Microassemby Platform P50

SmarAct Automation’s P50 manufacturing platform acts as a reliable basis into which your process can be integrated to offer you the most suitable system without the necessity to develop the entire production environment from scratch. The P50 provides for the fundamental infrastructure with a secure, future-proof and reliable foundation to transfer your promising idea from the lab to successful serial production.

Its modular structure offers fully automated manufacturing capabilities in combination with easy accessibility for set-up, maintenance and service to keep downtimes low and to adapt to changes in the product’s life cycle. The platform life cycle can be extended well beyond the initial process by constantly adapting, revising and adding new modules to fit new variants or even entirely new products. Every P50 is delivered as an individual turn-key solution that can be set up by our professional team of technicians to ensure a seamless start of production within your facility.

The control interface offers one-touch operation. At the same time, you have full control over the process and even the option to make changes to specific scripts directly in the HMI, depending on the operator’s administration rights. This is made possible by various interface options, ranging from a simple operator GUI that guides the user through the processes with short and engaging video tutorials, to a full-featured developer interface with the ability to load, customize and execute Python scripts via a scripting interface.

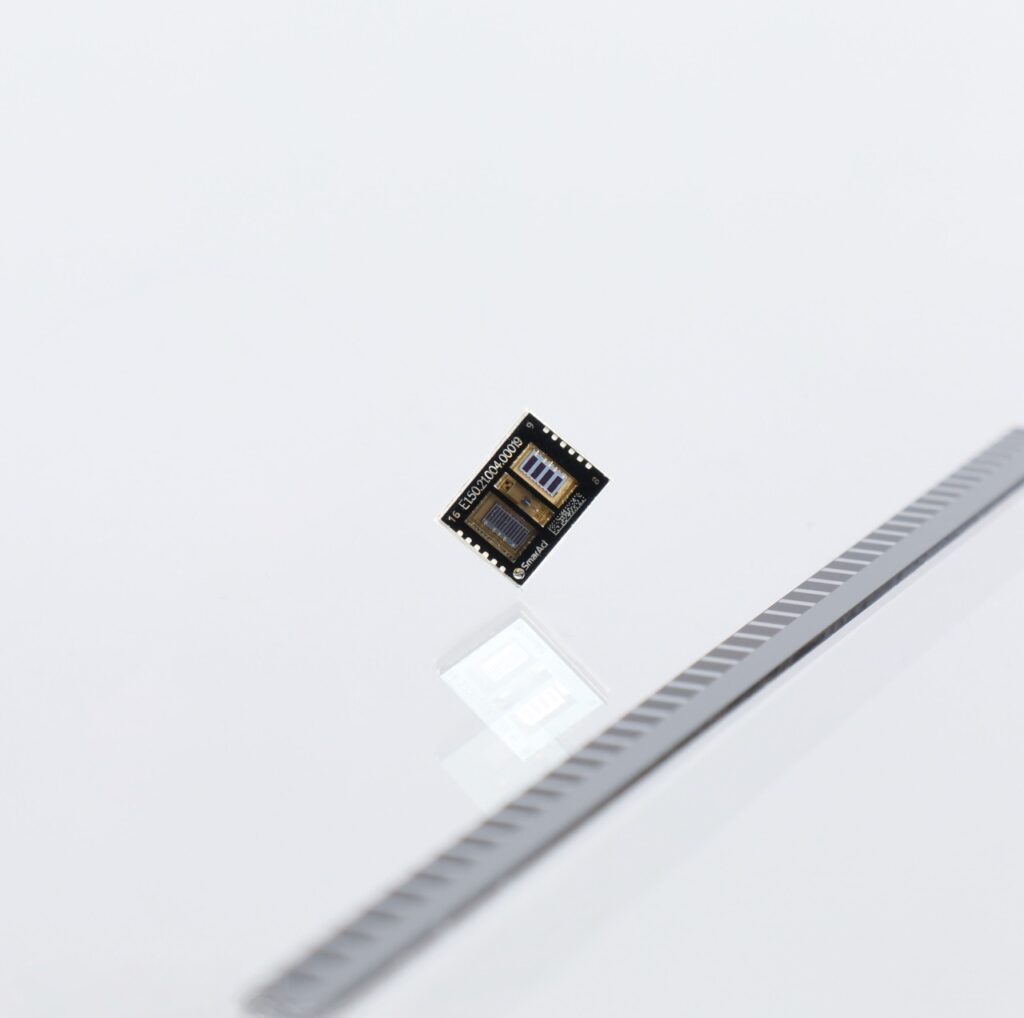

Compact Optical Encoders with Sub-Nanometer Resolution

SmarAct Metrology’s METIRIO® is a state-of-the-art, high-precision optical encoder designed and manufactured to meet the most stringent market requirements for closed-loop nano-positioning. The development of the device is based on many years of experience and extensive product and market analysis, and takes into account essential design rules to meet today’s technical challenges. It features maximum miniaturization, high resolution and speed. The readhead is modular and can be supplied as an OEM product or built into a customized metal housing to facilitate the integration process and ease of use. METIRIO® sets new standards in terms of low power consumption and UHV use. The graphical user interface of the associated software includes smart functions to simplify parameter settings, and all parameters can be stored in the internal memory for possible recall. The METIRIO® encoder is designed to measure all reflective incremental scales with 20 µm pitch, including reference mark detection.

The METIRIO® product portfolio is consistently modular. Core product is the METIRIO® Readhead, which can be used on its own, e.g. by OEM customers. If requested, the readhead can be purchased with additional functions and housings, so that a wide range of customer requirements can be met. The choice between METIRIO® Readhead and other modular housing variants opens up a wide range of installation options for METIRIO® encoders such as direct soldering, soldering on PCB, mounting via screws or adhesive mounting.