SmarAct – Your Partner for High Precision in Positioning, Automation and Metrology

With market-leading solutions in high-precision positioning, micro-automation, and metrology, SmarAct empowers researchers and innovators to achieve unprecedented levels of precision and productivity in their fields. SmarAct’s extensive product portfolio – including single-axis positioning stages, complex parallel kinematics, miniaturized robots, control systems, and advanced measurement technology – is complemented by automated micro-assembly solutions. Each solution is backed by SmarAct’s commitment to adaptability and quality through complete in-house production. This combination of expertise and customer-focused service ensures that SmarAct can meet even the most challenging application requirements. Supported by years of experience and a passionate team, SmarAct is a trusted partner for realizing ambitious goals.

Positioning Systems for Optical Component Microassembly

The SmarAct Gantry System is engineered to provide unmatched precision in alignment and microassembly, making it the ideal solution for applications requiring extreme accuracy and stability, such as in photonics, semiconductor manufacturing, and scientific research. Based on SMARSHIFT® electromagnetic direct drives, this system delivers nano-level precision combined with rapid motion, allowing for seamless handling and assembly of optical components like lenses, prisms and optical fibers. Combined with SmarAct’s handling modules, SMARFLEX® fast scan and alignment technology, and multi-axis SMARPOD and TRIPOD systems, the SmarAct Gantry System minimizes manual intervention while maximizing productivity. Its modular design integrates effortlessly into a wide range of workflows and can be customized to meet specific operational needs, offering flexibility across industries and research environments.

Microassemby Platform P50

SmarAct Automation’s P50 platform is an innovative foundation for seamless transition from laboratory concepts to full-scale production, encompassing not only the hardware setup but also the automation of your entire process workflow. This platform is designed to provide a future-proof, modular infrastructure that supports fully automated microassembly capabilities. Built for adaptability, the P50 minimizes downtime with easy access for setup, maintenance, and service, ensuring efficiency throughout its lifecycle. The platform’s modular design means it can grow alongside your production needs, accommodating new product variants and evolving applications through the integration of additional modules.

Each P50 platform is a turnkey solution, tailored to meet the specific requirements of your production environment. To simplify operations, the P50 features a control interface that allows one-touch functionality. Users are guided through each process step with short, engaging video tutorials, while developers have the flexibility to adjust and run Python scripts directly from the HMI, enabling customizable, real-time process control. From setup to advanced process automation, SmarAct’s P50 is engineered to streamline complex microassembly workflows and scale with your success.

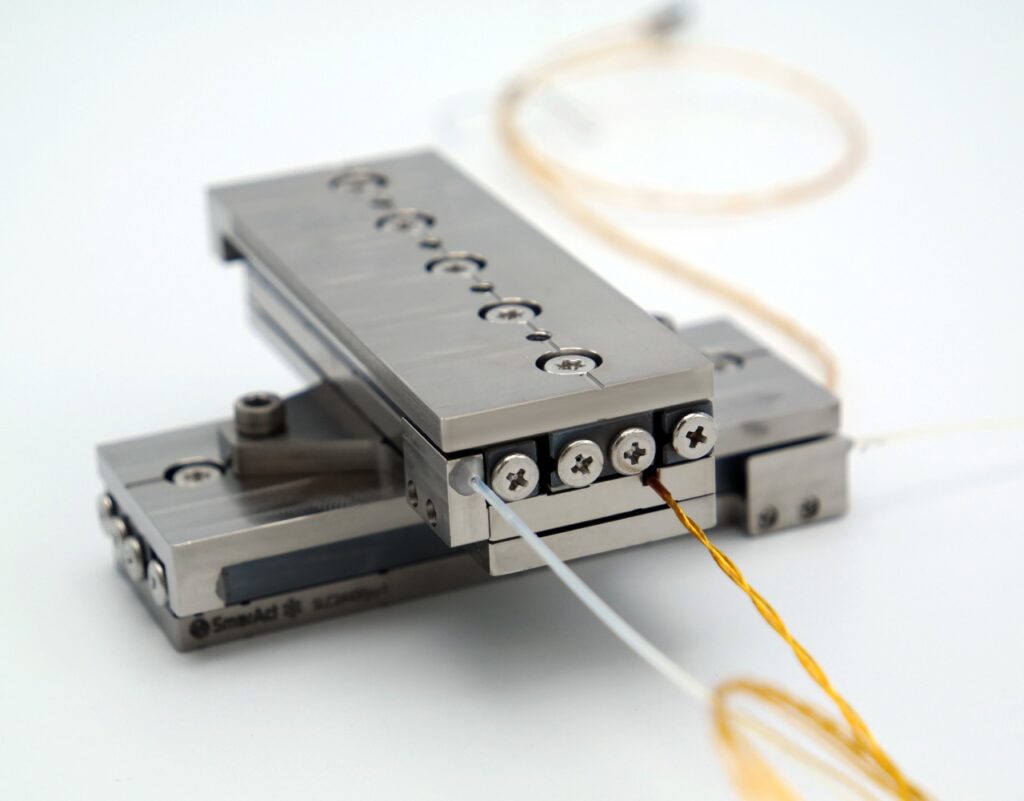

Electromagnetic Direct Drives

SmarAct’s SMARSHIFT®-equipped electromagnetic direct drives offer high-speed, nanometer-precise positioning, providing a valuable solution for industrial processes, laboratory automation, and compact positioning applications requiring both power and precision. These positioners feature non-contact electromagnetic drives that operate with minimal wear, enabling highly dynamic motion at speeds of up to 1 m/s while maintaining precision. The compact design allows for seamless integration into existing systems, with the durability to withstand intensive usage. This drive series is compatible with SmarAct’s piezo-driven stages, creating versatile systems that can accommodate a range of mounting options, such as base plates and pneumatic support for handling static or variable loads. The SMARSHIFT® motors and MCS2 controller series combine to deliver robust, high-performance solutions for demanding applications.

Scanner Stages

The SMARFLEX® scanner stages from SmarAct are designed to deliver ultra-precise scanning for applications that demand fine control and high repeatability. Using lever-amplified piezo actuators, these stages enable smooth, continuous motion with high dynamic capability, supported by FEM-optimized flexures that ensure vibration-free positioning. The stages can be combined to create multi-axis scanning systems, and integrated position sensing allows for closed-loop control with nanometer resolution, ensuring that each movement is precise and repeatable. These scanner stages meet the stringent requirements of industries and research fields where stability, repeatability, and high-speed performance are essential.

Closed-Loop Cryogenic Stages for Quantum Computing

SmarAct’s advanced closed-loop cryogenic stages provide a precision solution for research applications that demand both high positional accuracy and thermal stability in low-temperature environments. These stages achieve resolutions below 0.5 nm and offer unidirectional repeatability down to 5 nm over a 1 mm travel range. With a robust design optimized for cryogenic conditions, SmarAct’s cryogenic stages are essential for high-performance applications in quantum technology and 2D materials science. The stages are available in non-magnetic versions for use in high magnetic fields, integrating SmarAct’s cutting-edge stick-slip piezo drive technology and PICOSCALE interferometric sensor heads, which ensure exact, reliable positioning. Additionally, custom configurations can be provided to meet unique research and application demands.

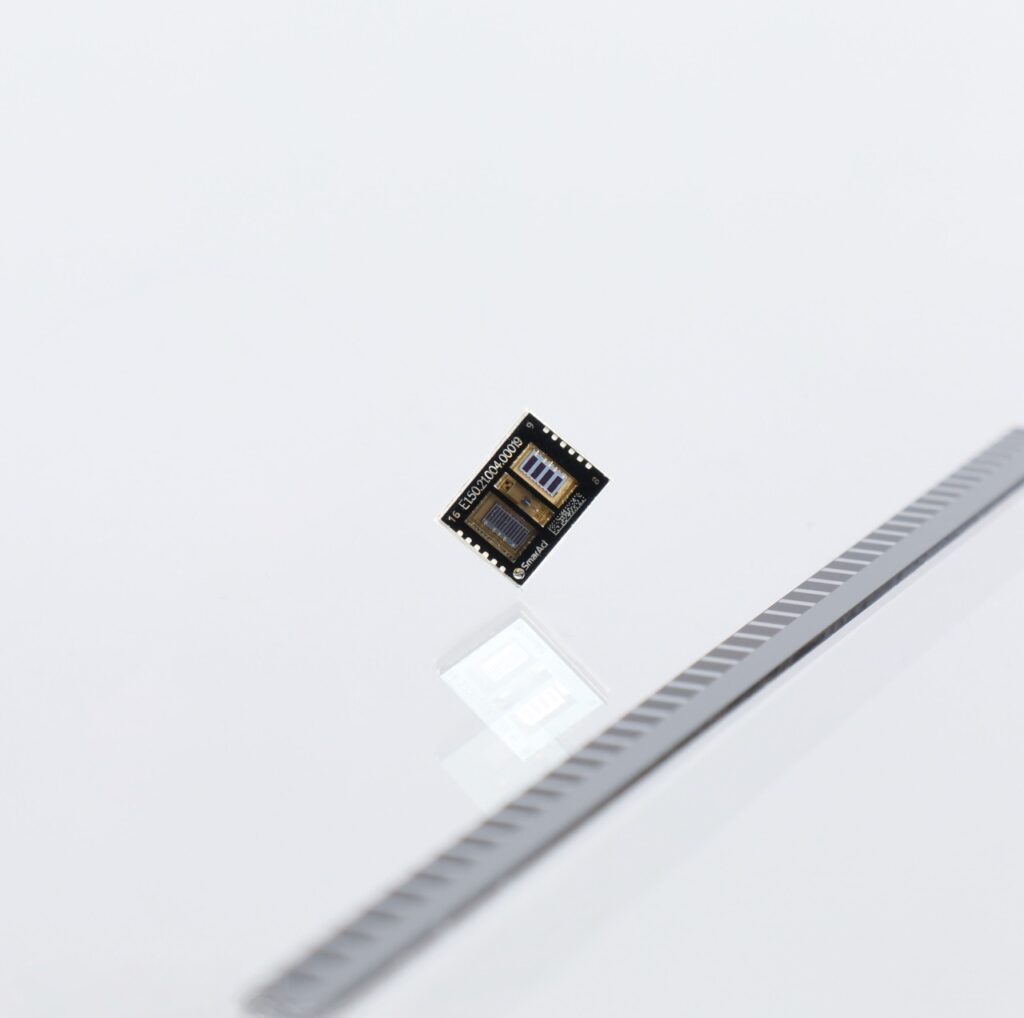

Compact Optical Encoders with Sub-Nanometer Resolution

The METIRIO® optical encoder from SmarAct Metrology represents a new benchmark in high-precision, closed-loop nano-positioning technology, combining ultra-compact design, sub-nanometer resolution, and high speed. Engineered for integration flexibility, the METIRIO® encoder comes as a standalone product or OEM component, with customizable housings and mounting options to fit diverse application needs. Designed with low outgassing materials and UHV compatibility, the encoder operates reliably in challenging environments and is ideal for fields that require extreme precision, such as metrology and semiconductor manufacturing.

METIRIO® achieves consistent performance across various scales, using reflective incremental scales with a 20 µm pitch, including reference mark detection. The accompanying software interface is intuitive, with smart functions that simplify setup and enable parameter storage for streamlined use across different tasks. METIRIO® encoders are highly adaptable, supporting linear, rotary, and goniometer applications, making them suitable for installations requiring both precision and modularity. With the METIRIO® encoder, SmarAct delivers a versatile, high-resolution solution designed to meet the rigorous demands of advanced nano-positioning applications.