LT Ultra Precision Technology GmbH

Tailor-made ultra-precision machines and the manufacturing of metal optic components are the strong core business of LT Ultra. With more than 30 years of experience in ultra precision machining today the company is a competence center for multi-axis diamond machining.

The scope of metal optics ranges from injection molds for small lenses to automotive lights, from barcode readers for logistic facilities to components for spectral analysis applications or particle accelerators – all over the world LT Ultra products and solutions secure the commercial success of our clients.

LT Ultra’s machine portfolio provides entire UP machines as well as key components like ultra-precision rotation stages and linear stages or interferometers. LT Ultra is a pioneer in integration of future-proof periphery and automation into our machines. Such as automatic tool-changers and tool-setting or in-situ measurement devices that allow producing and measuring of the work piece in one setting. Your benefits are unique precision, time saving and security of investment. Get your machine solution tailored specifically to your requirements. The unparalleled manufacturing depth guarantees highest reliability and contemporary pricing.

As a privately owned company, LT Ultra cooperates with its customers on a long-term relationship. Our experts provide intensive consulting and a close cooperation from the beginning.

Metal optics and tools

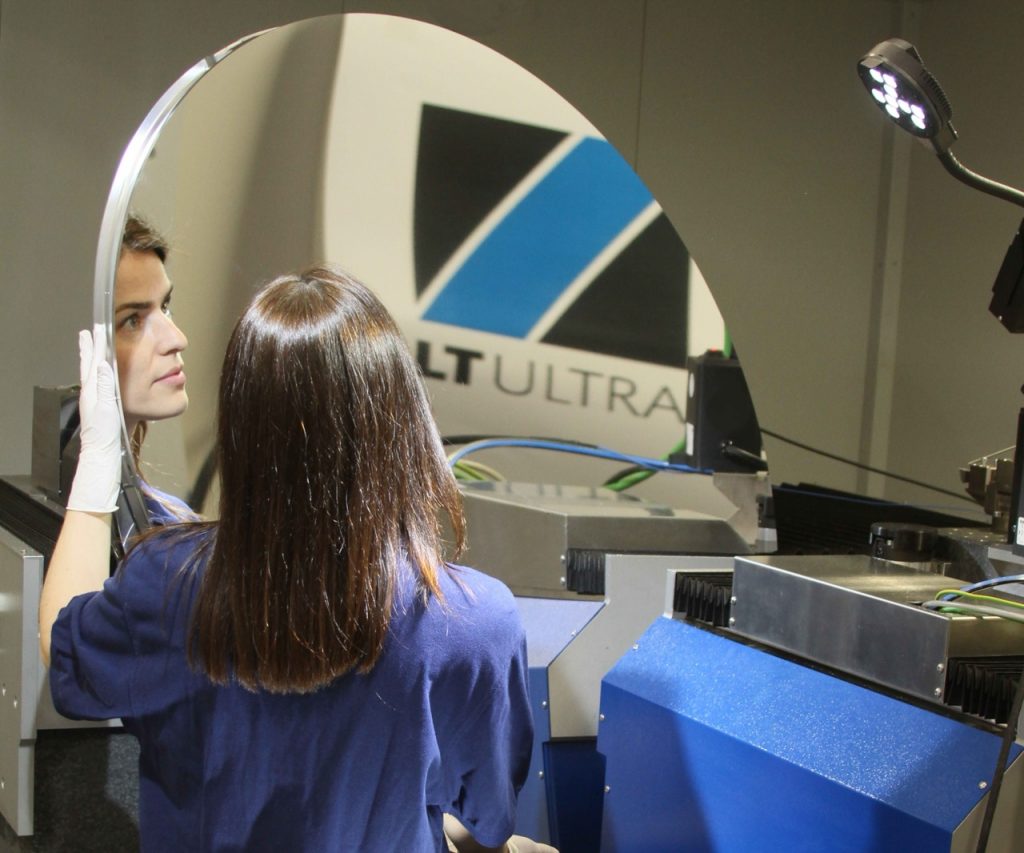

LT Ultra produces metal optics on self-developed machines.

- Highest precision of parts regarding contours, roughness, surface quality

- Outstanding price-performance-ratio

- From single part to mass production

- Fast delivery

- More than 40 UP machines in contract manufacturing

- Various refinement options, e.g. high-performance coatings

- Aerospace and Defence

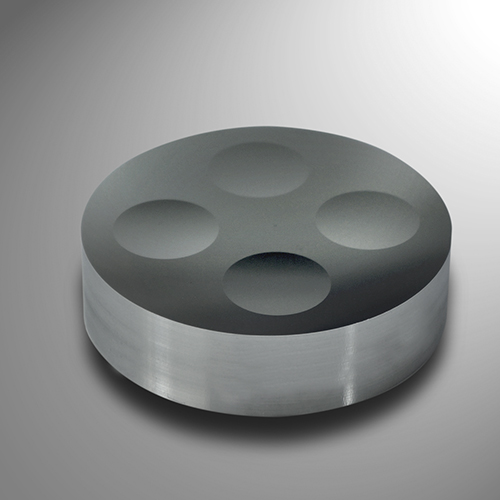

Freeform optic (aluminum)

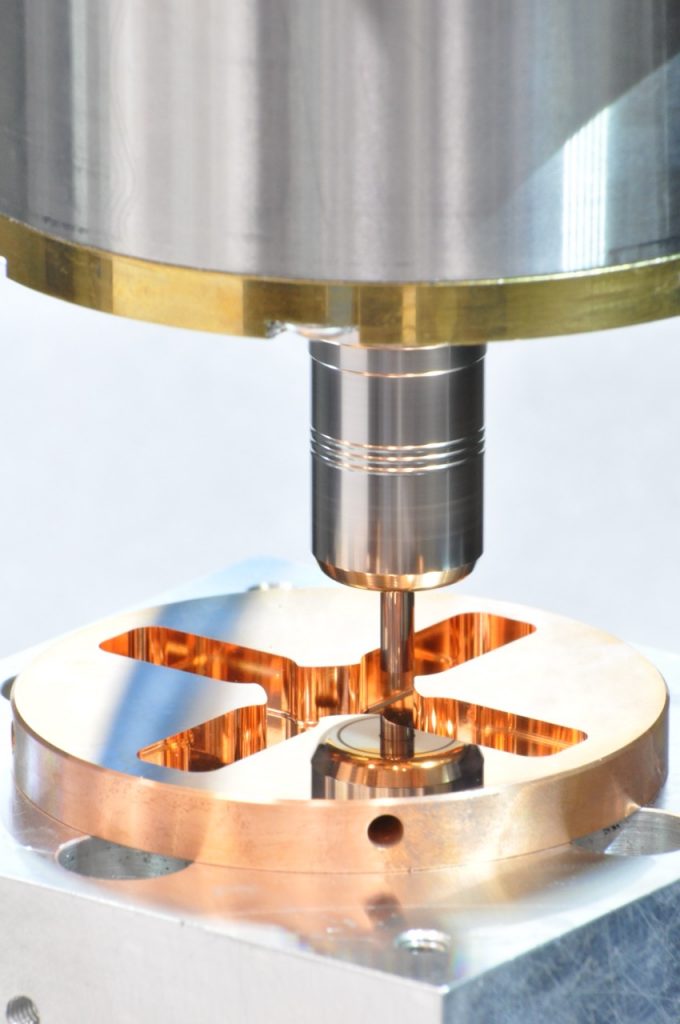

Particle accelerator component (copper)

Range of products.

- Plane and spherical mirrors

- Aspherical mirrors

- Polygon and scanning mirrors

- Freeform and adaptive optics

- Ultra-precision milling parts

- Structured optics

- Mould inserts and embossing tools

Company profile

Employees: ~ 150

Production area: > 11 000 m²

Founded: 1995

Ultra-precision machines

LT Ultra has a continuous portfolio from UP-turning and -milling machines, to large embossing roller turning machines.

- UP-turning, -milling, -planing, -grinding, -polishing,

- -micro structuring, -engraving, -measuring

- Extreme contour accuracy and surface quality

- Bearing systems free of stick-slip for increments <10 nm

- Range of standard machines

- Customized machines or even built from scratch according

- to your needs

- Accessories that range from different spindles to fast tool axes or from automatic tool changers to in-situ measurement devices

- Interferometer 4-12 in (stand-alone or build in)

Special purpose machines – CUSTOMized

- Ultra-precise machining solutions tailored to your needs

- Consulting, planning, design, concept, setup and commissioning

- The recipe: customer-specific solutions developed in a short time frame and in close collaboration

- The ingredients: granite, air/oil bearings, precision drives,

- high resolution scales, software, automation

- The Result: the optimum solution for the production of your parts with roughness values and precision in the nanometer range

Machine components and hydrostatic bearings

LT Ultra constantly enhances the range of components.

- Ultra-precision linear and rotary bearings free of stick-slip

- Air- or Oil-hydrostatic bearings

- Available with various drive systems and scales

- From a few centimeters up to a few meters in size

- Load capacities from a few kilograms to several tons

- Customized to fit your machine or measurement setup

Linear and rotary bearings

Linear and rotary bearings

Beam Delivery Components

Complex components in particular are in good hands with LT Ultra

- Design, layout and manufacturing of motorized optomechanical

- components

- Used for many years in various industries and applications

- Temperature-stable & air-conditioned assembly areas, flow boxes, clean rooms

- Broad range of customer specific products

- Standard range products: 3D cutting heads with up to 3 axes, telescopes, beam benders and more