Lasermet Europe GmbH

CaLM System

The CaLM System is an essential tool for professionals working in laser-

controlled areas (LCA), providing both convenience and safety. By monitoring and controlling an entire interlocked laboratory on a large screen, this system ensures that users have complete control over their workspace, reducing the risk of accidents and ensuring optimal performance.

The CaLM System consists of a control box and a large screen monitor that are seamlessly connected to the laboratory’s Interlock System. This integration allows for real-time monitoring and control of various safety aspects within the laboratory environment.

One of the key features of the CaLM System is its ability to adapt to the unique requirements of each laboratory setup. Since every laboratory is unique in its layout and equipment, the CaLM System is custom programmed to replicate the customer’s specific configuration. This ensures that the system operates in sync with the laboratory’s interlock system, guaranteeing seamless compatibility and optimal performance.

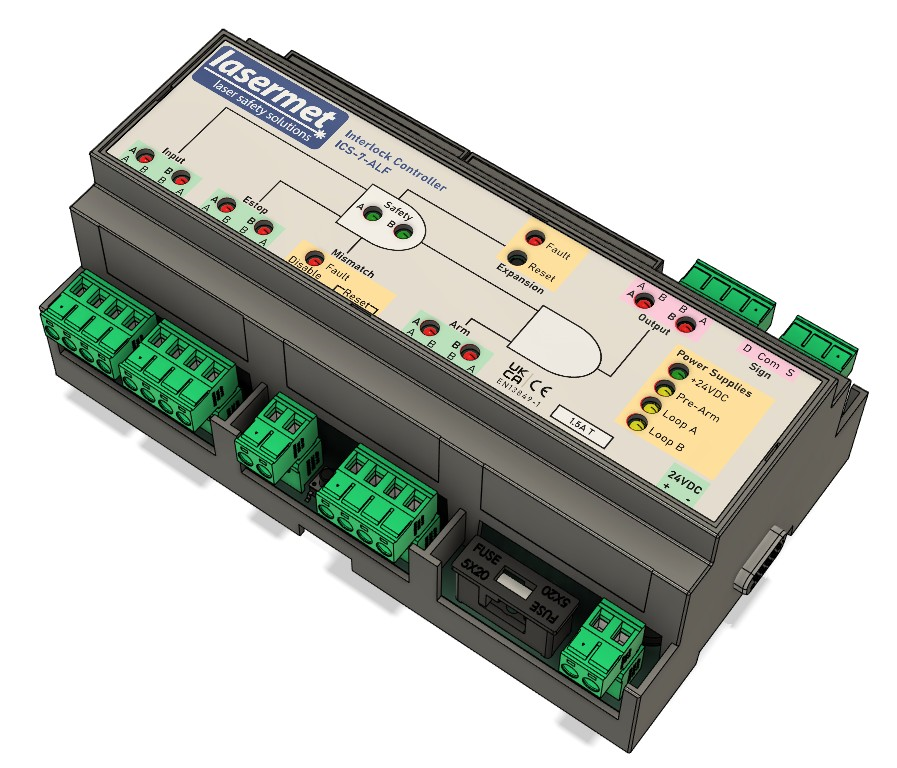

Lasermet ICS-7 ALF

The Lasermet ICS-7 ALF is the latest addition of the Interlocked Control System (ICS) series, specifically tailored for use with the Passive Alf interlocked laser welding helmet and enclosure. With its precise engineering and comprehensive features, the ICS-7 ALF contributes to the overall safety and performance of hand-held laser welding operations that it is ready to seamlessly integrate with the Passive Alf interlocked laser welding helmet.

Its compact size makes it a versatile choice for various applications, while the option to include active guarding components ensures readiness for future upgrades.

Experts in the handheld laser welding industry can enhance their safety protocols, mitigate risks, and improve efficiency in their operations. This product exemplifies our commitment to delivering high-quality, technologically advanced solutions that meet the needs of professionals who prioritize safety and performance.

New Lasermet facility expansion

Boosting innovation and delivering the highest standards of laser safety products and services worldwide.

We are pleased to announce the completion of our new facilities at Lasermet’s northern operations site. These new facilities have been specifically designed to meet the growing demand for our laser safety products, which are trusted and utilized by professionals worldwide.

Located in the esteemed M7 Haydock Industrial Estate, our new facilities encompass the original Lot #11 (6,000 sqm) and Lot #12 (5,000 sqm), providing us with space for the manufacturing of our high-quality products.

Furthermore, on September 18, 2023, we successfully acquired Lot #13, which boasts a spacious 8,000 sqm area dedicated to storage and advanced packaging capabilities, enabling efficient dispatch of our products to customers around the globe and accommodating our growing operations.

A standout feature of Lot #13 is our impressive 1,500 sqm showroom. Within this showcase space, we will proudly exhibit the latest technological advancements that Lasermet has to offer.

This showroom serves as a platform to demonstrate the exceptional performance and superior safety features of our products, allowing professionals to make informed decisions about their safety equipment.

Our new showroom not only adds a touch of grandeur to our facilities, but it also serves as an interactive platform for our ustomers to explore and experience the most advanced laser safety technology available on the market.

At Lasermet, we are committed to providing our customers with cutting-edge technology that prioritizes their safety and enhances their efficiency. With our new facilities, we can continue to innovate and deliver the highest standard of laser safety products and services, ensuring the well-being and protection of professionals in the laser welding industry.