IMT - Where Optics meets Microfluidics

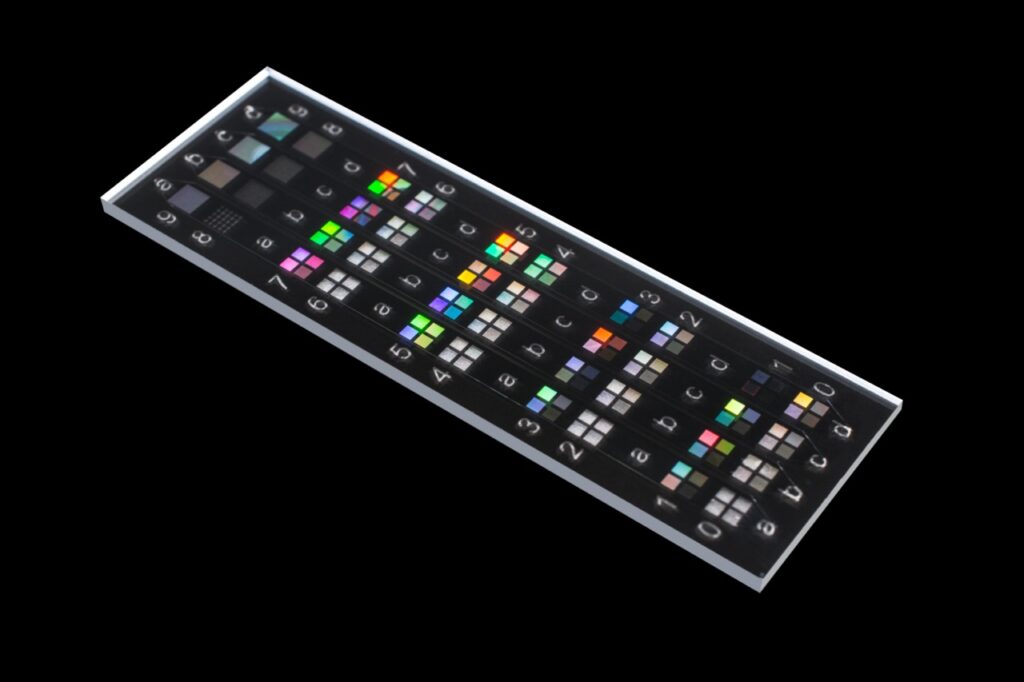

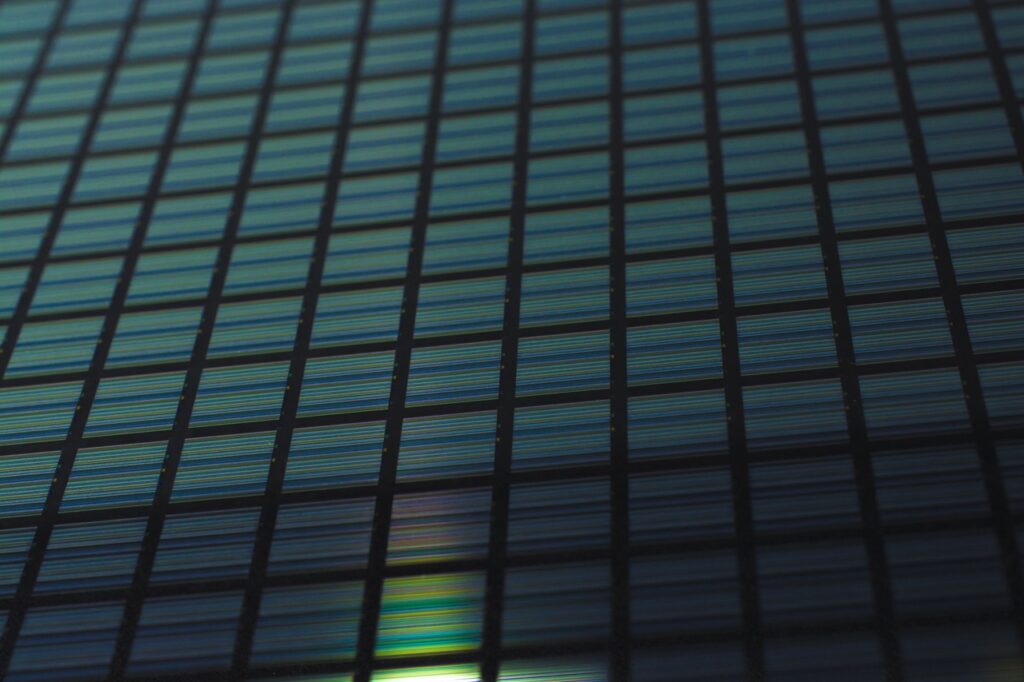

IMT Masken und Teilungen AG comprises profound experience in the design and manufacturing of micro- and nanostructures on and in glass. In close cooperation with our partners and customers we offer leading edge foundry services in the field of micro-optical components and microfluidic chips/consumables.

We provide design support starting at the early development stage all the way through to volume production. Semiconductor technology along the entire manufacturing process allows for production of cost-effective glass components of a consistently high quality and high throughput.

All manufacturing processes like, lithography, etching, sputtering of metal- or dielectric coatings, and final dicing are based on 200mm- wafer technology.

Our key enabling elements are used in a huge variety of optical applications such as Semicon Industry, 3D-Sensing, Optical Metrology, Medical and Life Sciences.

Besides optical applications our manufacturing technology enables us to provide our customers with components where optical, electrical and microfluidic functionalities are combined. These biochips contain micro-channels, TGVs and metallic/ dielectric microstructures in combination with e.g. optical waveguides.

Before dicing to final geometry wafers can be hermetically sealed while employing state of the art fusion– or room temperature bonding.

IMT at a glance:

- Foundry for the design and production of microoptical and

microfluidic components - Employees: 130

- Clean room: 1300m2

- Location: Greifensee (Zurich), Switzerland

IMT Masken und Teilungen AG is a subsidiary in the HEIDENHAIN Group of companies.