C-Flex Bearings: Precision Motion for Optical Systems

In the optics and photonics world, precision can’t be compromised. From laser scanners and beam-steering mirrors to telescopes and metrology instruments, even tiny mechanical errors can degrade system performance. C-Flex Bearing Company is a specialist in flexure-based pivot bearings that deliver frictionless, backlash-free motion without the use of lubrication and without wear. For optical engineers, this means reliable, consistent motion over millions of cycles.

Application Highlights

Beam Steering & Scanning Mirrors

Frictionless oscillation for millions of cycles ensures accurate, repeatable laser scanning.

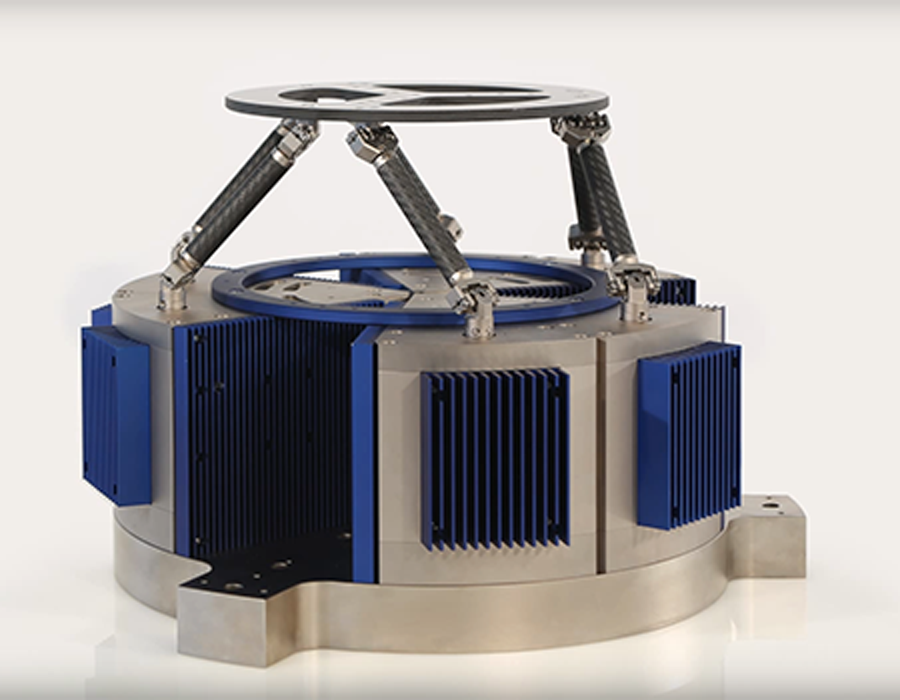

Gimbals & Pointing Mechanisms

Backlash-free pivots stabilize telescopes, sensors, and imaging devices.

Optical Mounts & Alignment Stages

Precise motion maintains instrument alignment over time.

Metrology & Interferometry Instruments

High stiffness and predictable motion support nanometer-level measurements.

Spaceborne Optical Systems

All-metal, lubrication-free, maintenance-free design operates reliably in vacuum and extreme temperatures.

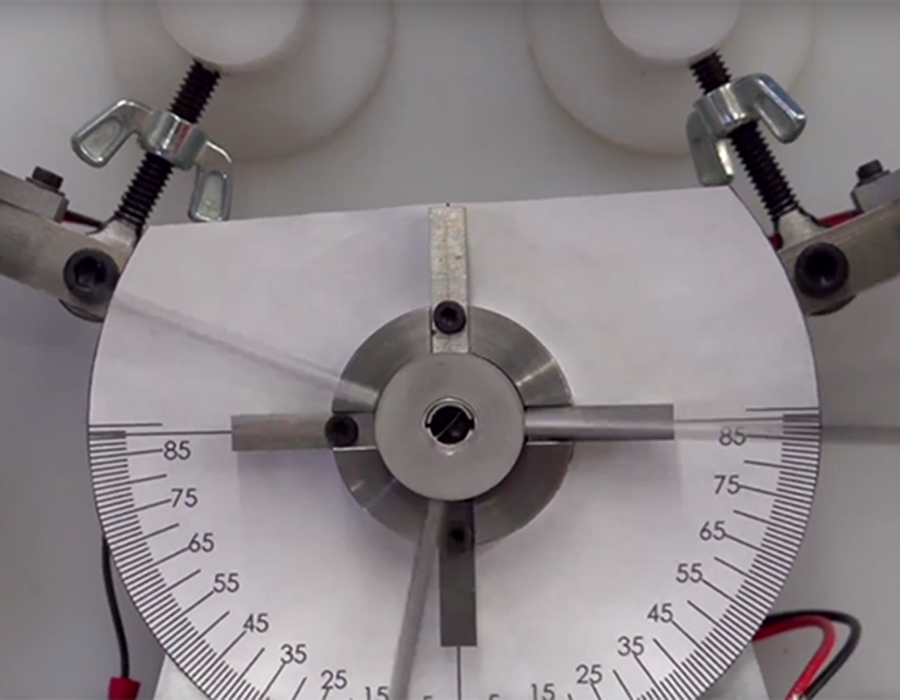

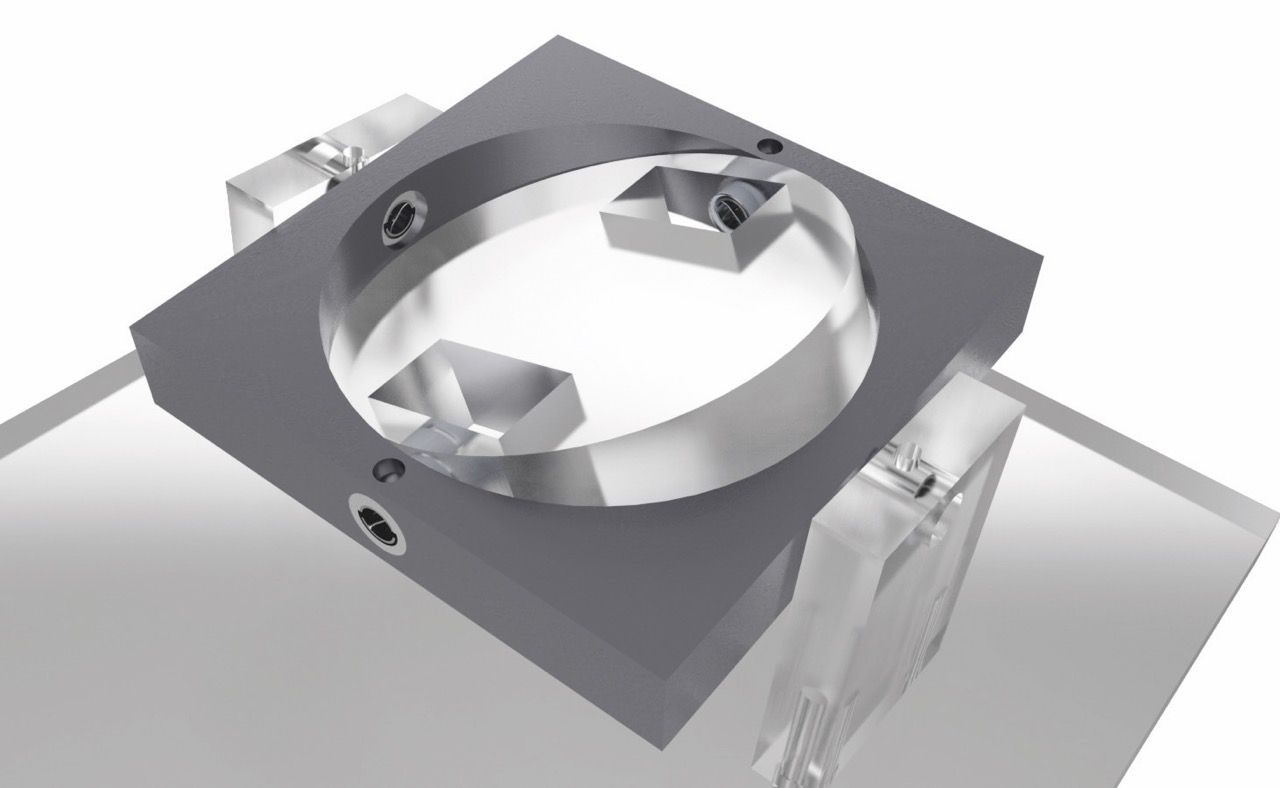

How does a Flex Pivot Bearing work

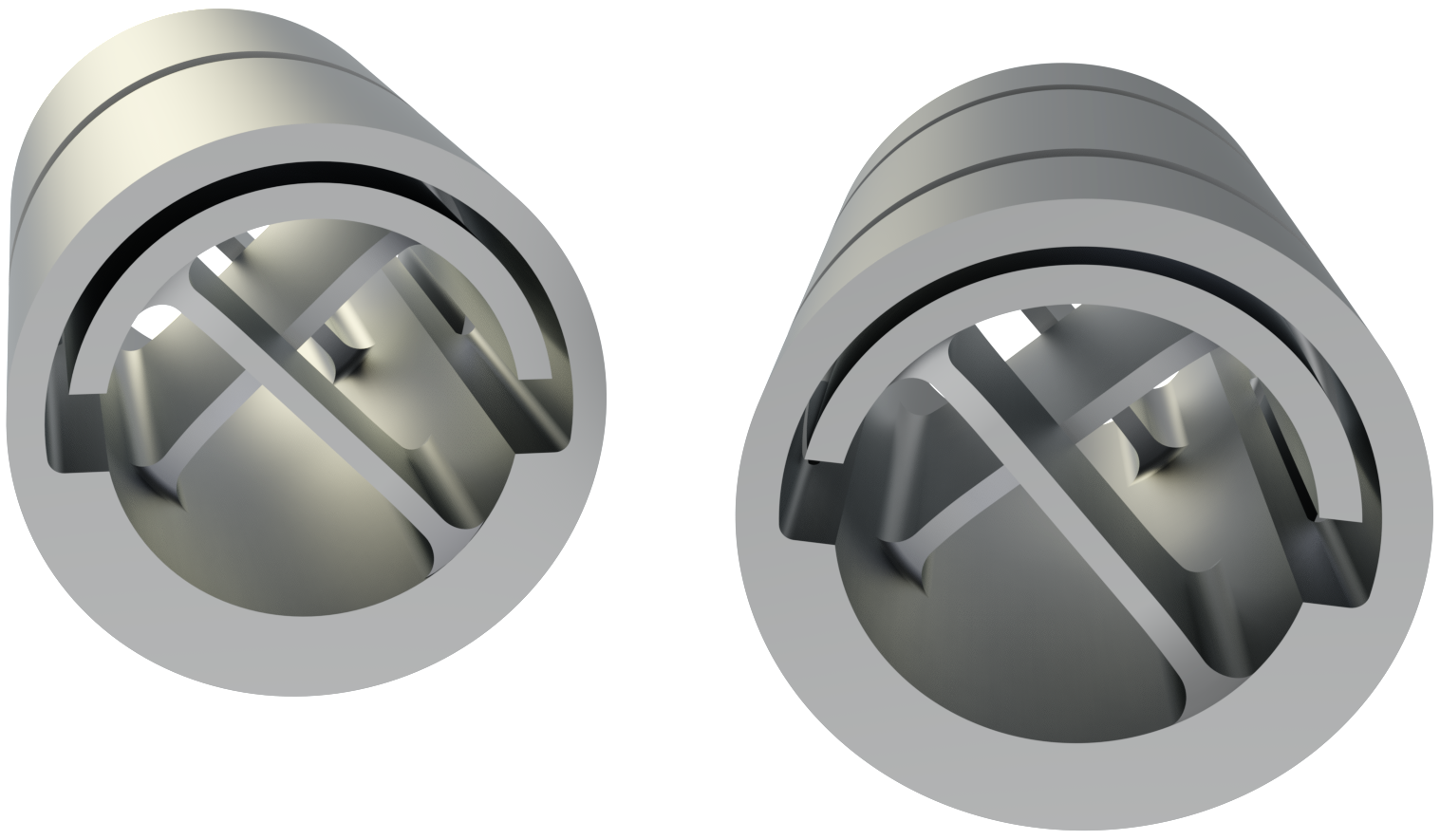

A Flex Bearing initially consists of two half-shells connected to each other by two crossed leaf springs, creating a slotted cylinder in terms of geometry. There are two designs in the standard series: the cantilever and the double-ended pivot. In a cantilever bearing, one of the half-shells is firmly connected to one sleeve.

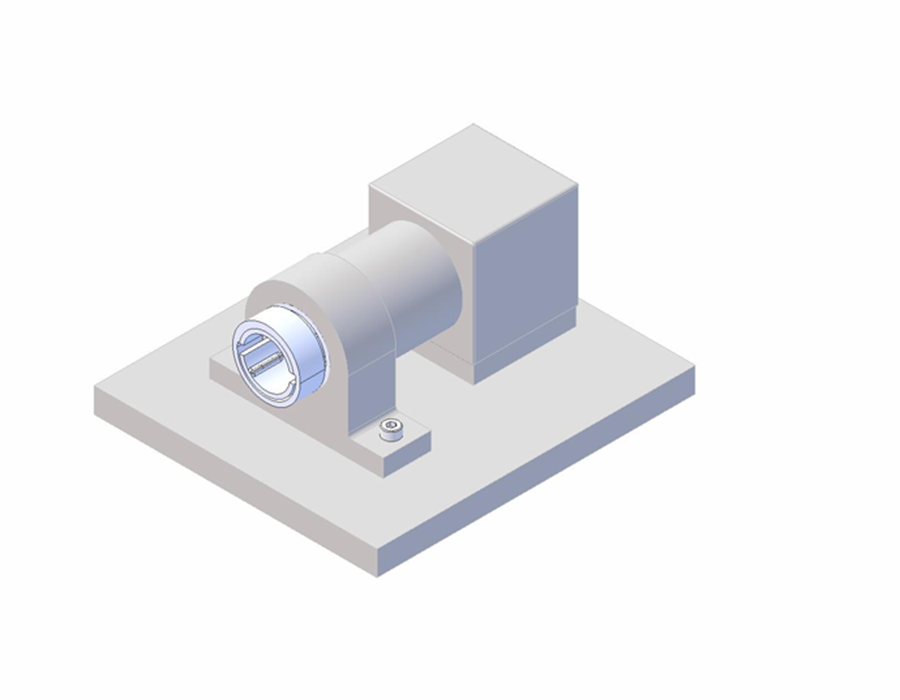

The elasticity of the leaf springs enables the two sleeves to rotate radially against each other. In the double-ended pivot design, one of the sleeves is split and positioned on one of the half-shells and is connected via the springs and the other half-shell with the unsplit sleeve in the middle. This design is more robust, but it requires two external bearing blocks.

The middle section can move freely against the narrow outer sleeves within the respective angle of rotation. As previously mentioned, the Flex Pivot is a cylindrical bearing designed for limited angular rotation. It offers relatively high stiffness against forces acting in the radial and axial directions.

The torsional stiffness of the ten different sizes can be selected in three spring strengths (10/20/30), which correspond to rotation angles of ±15°, ±7.5° and ±3.7° respectively.

Details of the available series can be found in the corresponding overview on the website:

www.g-a-d.de and www.c-flex.com

Why C-Flex Bearings Matter

Traditional bearings rely on rolling or sliding surfaces, which can introduce friction, stiction, wear, hysteresis and backlash – challenges amplified in sensitive optical systems. C-Flex pivots work differently. Elastic leaf springs allow rotation without contact, providing:

- Smooth, repeatable motion

- Maintenance-free operation

- Predictable torsional stiffness

- Long-term reliability for millions of cycles

Maximum angular range is ±30° and custom designs are available. The design ensures repeatability, stability, and alignment accuracy, even under extreme environments such as vacuum, cleanroom, or space conditions.

Engineering Support & Customization

C-Flex offers more than just components. The company offers:

- CAD models and 3D drawings

- Detailed specifications and design guides

- Technical support for seamless integration

- Custom designs for specific angular ranges, stiffness, or geometry

All products are manufactured, assembled and tested in Frankfort, New York, USA, ensuring consistent quality and performance for optical engineers worldwide.

Sizes

The sizes range from 1/8“(3.175 mm) to 1” (25.4 mm) in diameter in 10 increments and 2 designs, each with 3 possible spring strengths, resulting in 60 different types of standard models made of stainless steel. Of course, custom Flex Pivots can also be manufactured from special materials such as Hast-X, Inconel, Beryllium, or Titanium with specific spring rates and specific sizes.

The C-Flex Advantage

Precision motion is foundational to optical system performance. C-Flex bearings provide clean, predictable, and maintenance-free motion, enabling engineers to focus on optical design rather than mechanical compromises. When repeatability, stability, and long-term reliability matter, C-Flex is a trusted partner for the optics and photonics industry.

Distributer Europe

GAD

Elektronik-Komponenten-Vertriebs GmbH

Gewerbering 11

68723 Plankstadt, Germany

+49 6202 926260

info@g-a-d.de

www.g-a-d.de

Manufacturer

C-Flex Bearing Company

Industrial Drive

Frankfort, NY 13340

+1 3158957454

cflex@c-flex.com

www.c-flex.com

Distributer FarEast

EM Fusion Pte. LTD.

33 Ubi Ave 3

Singapore 408868

+65 6844 6400

enquiry@emfusion.com.sg

www.emfusion.com.sg