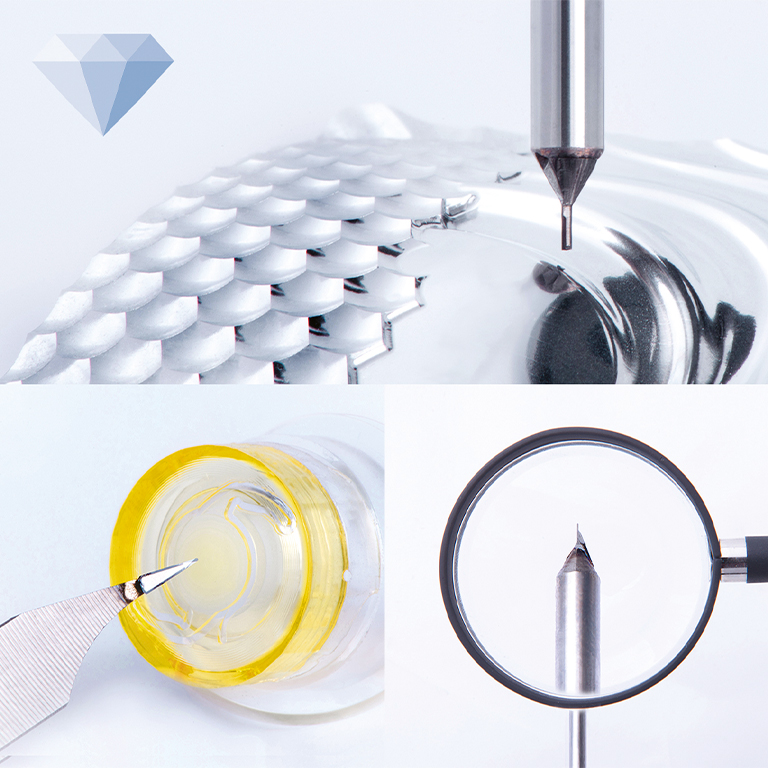

Specialized High-precision Diamond Tools for Turning and Milling

DiaTec Diamanttechnik GmbH is the leading producer of high-precision diamond tools in the high-end sector. With the machines that we have developed and the most modern techniques, we produce customized turning and milling tools with diamond (MCD), PCD and CBN edges.

As an experienced producer, we make diamond tools with tolerances in the μm range and roughnesses in the nanometre range. With gap-free polished diamond edges, surface roughnesses of 3 – 6 nanometres can be reached. These tools guarantee perfect results with excellent tool life. For the production of our tools, we use selected cutting materials of the highest caliber, corresponding with individual customer specifications.

Diamond milling tools for mirror finish surfaces without further treatment

You can rely on our Years of experience in the construction and application of diamond milling tools. Custom-made DIATEC milling tools are used where the highest demands are made regarding the surface finish. With DIATEC tools, perfect mirror, sealing and sliding surfaces can be produced without any further polishing – even in difficult applications.

Our tools

- mini milling cutters from Ø 0.10 mm

- engraving milling cutters from Ø 0.05 mm

- radius milling cutters from Ø 0.10 mm

- end milling cutters from Ø 0.10 mm

- single tooth milling cutters from Ø 0.10 mm

- face milling cutters from Ø 0.10 mm

- milling heads up to Ø 200 mm

Fields of application

- laser mirrors, automobile headlights, LED lamps, acrylics with distortion-free reflecting surfaces, mould making, micromechanics, jewelry and watches

Processible materials

- Non-ferrous metals: gold, silver, platinum, nickel, brass, germanium, silicon, aluminium, copper and bronze

- Plastics: acrylics (PMMA), polycarbonate (PC), polyvinyl chloride (PVC), polyethylene (PE) and polyoxymethylene (POM)

Diamond turning tools for polish turning

DIATEC turning tools made of monocrystalline diamond are used for the ultra-precision machining of watches, optical industry, jewellery production and in precision mechanics.

On vibration-free machines, specifically produced for polish turning surfaces with surface roughnesses in the nanometre range, can be created and compared to a mirror. Finishing with sanding or polishing is no longer necessary. Compared to polishing, contours and measurements remain completely unchanged. Even in microscopic magnification, no tool marks are visible.

Our tools

- turning tools for internal and external machining

- profile turning tools

Fields of application

- polish turning in the optical industry, jewelry production and precision mechanics

Processible materials

- Non-ferrous metals: gold, silver, platinum, nickel, brass, germanium, silicon, aluminium, copper and bronze

- Plastics: acrylics (PMMA), polycarbonate (PC), polyvinyl chloride (PVC), polyethylene (PE) and polyoxymethylene (POM)

Tools with controlled waviness

DiaTec offers tools with controlled waviness for machining lenses on CNC 2-axes lathes. The definition of waviness is the amount of deviation from a true circle. As tools with controlled waviness are considerably more expensive, it is important to also be able to measure the specified waviness. Using the latest generation of measuring equipment, DiaTec can guarantee the specified waviness. The tools are inspected using 800x Normanski optics. All holders are produced in house. This tools are offered with the following features:

- insert system or solid shank tools, cylindrical or conical clearance

- natural or single crystal synthetic diamond

- guaranteed waviness of 0.25µm, 0n request up to 0.05µm

- various geometries (radius of 0.01 – request size) rake like request

Technical support and service

DiaTec provides tools for testing. Tests establish the correct tool configuration for diamond material, radius, clearance, rake and waviness. DiaTec offers service of polishing for all kind of tools on the market.