Bühler Leybold Optics. Solutions for every challenge.

As one of the world leaders in thin film technology, Bühler Leybold Optics, is developing and manufacturing vacuum deposition equipment for a broad range of applications. As part of Bühler Group, Bühler Leybold Optics is a globally active high-tech company, present in more than 40 countries with main production facilities in Alzenau (Germany), Beijng (China) and Cary (USA), and world-wide over 425 employees. Bühler Leybold Optics offers thin film vacuum deposition system for the precision optics industry among others. A top priority of the company is innovation leadership in key areas such as sputtering, PECVD, plasma assisted evaporation, machine automation and software, as well as world-class customer service.

Solutions for different applications. Coating Equipment.

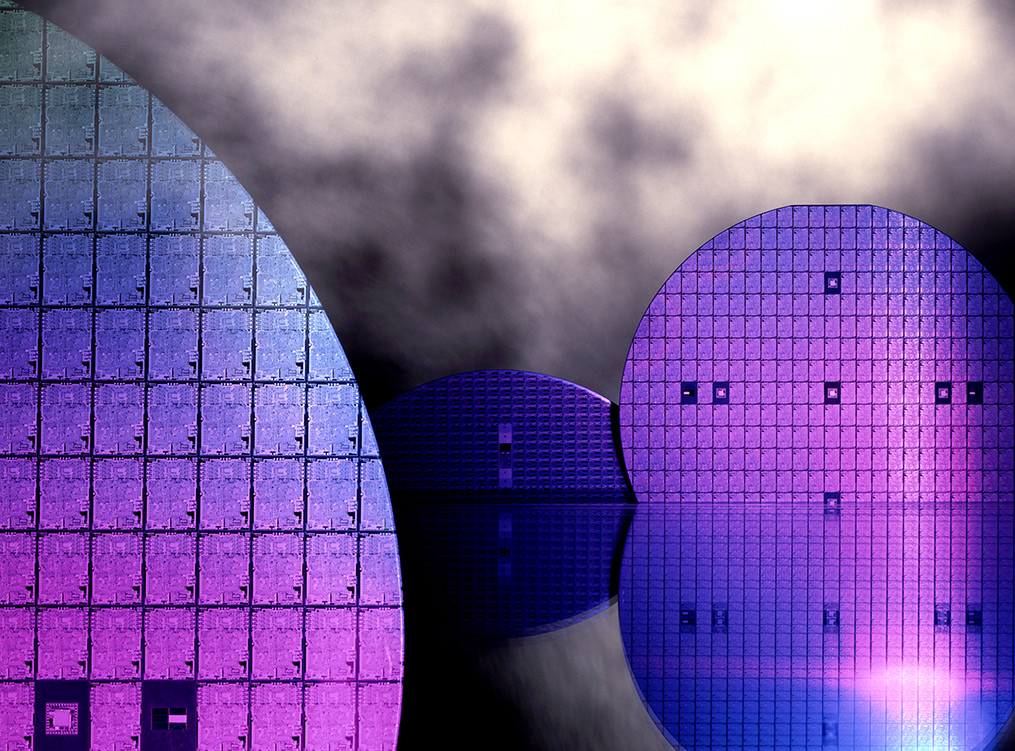

NESSY Series

Our latest-generation of magnetron-sputtering for the production of extreme ultraviolet (EUV) mirrors under ultra-high vacuum (UHV) conditions – for mass production and product development.

DEIMOS

Astronomical mirrors of up to 4.5 m in diameter can be precisely sputtered, achieving highest reflectivity and durability values. Easy exchange of substrates.

SYRUSpro Series

The industry benchmark in production and R&D. Classical evaporation system producing excellent coatings. Also available in configurations for infrared (IR) and ultraviolet (UV) wavelength regimes.

LEYBOLD OPTICS DLC

Plasma-enhanced chemical vapor deposition (PECVD) technology for diamond-like carbon coatings. Mainly used for night vision- and thermal-imaging systems.

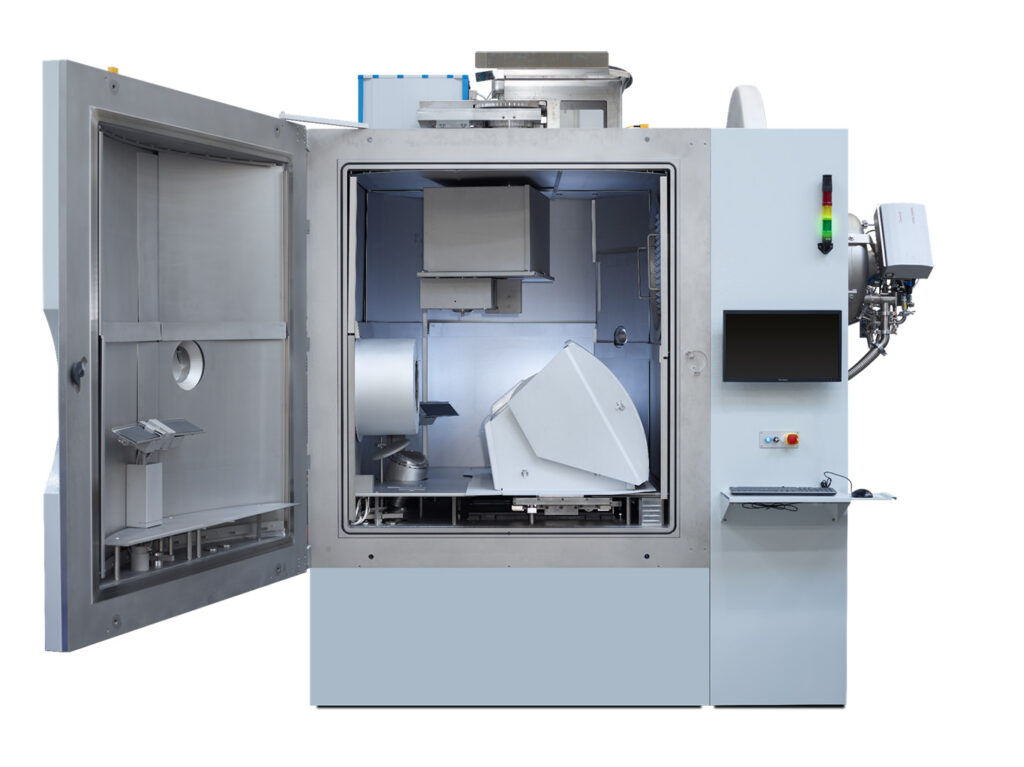

HELIOS Series

The HELIOS series sputtering tool is a flexible platform for fast, precise and fully-automated thin-film coatings. It specializes in high-quality optical coatings featuring very low absorption and scattering.

Our two NEW HELIOS tools for outstanding performance

Applying high grade complex optical filters combined with high productivity: HELIOS 800 for 200 mm & HELIOS 1200 for 300 mm glass and active device wafers.

LEYBOLD OPTICS IBF

Our ion beam figuring system for the production of surfaces with an extreme high precision of a few nanometers and a lateral resolution in the submillimeter range. It is a dry error correcting and polishing process under vacuum where accelerated argon atoms ablate minuscule particles from the surface of the workpiece. Nearly all geometries and materials can be processed.

LEYBOLD OPTICS IBS

Our ion beam sputtering system for the production of high-precision optical coatings. The technology is well known for extremely low-loss optical coatings. The machine is a batch type system, optional with an automatic load lock system and equipped with an extremely powerful 3-grid RF ion beam source able to produce large substrates with corresponding quality and speed.