Sill Optics News

Visit Sill Optics at Laser World of Photonics in Munich, 24. – 27. 06. 2019, Messe München Hall B3 / Stand 302.

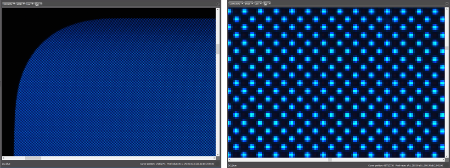

Industrial 3D printing – Additive manufacturing

3D printing or rather additive manufacturing is the layer by layer building of components from fine powder. Powder materials can be plastics, metals or even composite materials. Digital 3D data is the basis of this process. Formerly used for samples, prototypes or small series this production technique is well established in mass production in various applications. Sill Optics offers a variety of lenses used in additive manufacturing. The most recent lens in this segment is the S4LFT0910/328. Designed for an aperture of up to 30 mm, combined with fused silica as lens material and the low absorption coating, the lens is the perfect choice for high power applications. Furthermore, its large scan field allows production of extended components.

Alignment turning for production of precision optics

The performance of a lens depends on its design, the surface shapes, but also on the position of all included lens elements. A minimum lateral offset and a minimum angle between element axis and optical axis have an important role to play. The conventional assembly method uses spacer rings to define the distance between unmounted lenses inside a tube body. Alignment turning enables a more accurate assembly, as well as high precision centering. The two-stage method is very useful especially for high end optics (e.g. space or microscope lenses). In contrast to the classic assembly method, alignment turning uses mounted lenses (phase 1: mounting). Optical methods enable an exact alignment of a single lens inside the device, hence lens axis and machine axis lie on top of each other. During the second phase the diameter, front and back face of the mount are turned off with ceramic tools. Centering tolerances of some micrometers are realizable. Even though the method is much more complex, its high accuracy enables new possibilities. Sill Optics uses alignment turning especially for custom specific lenses with high centering specifications.

More news you can find HERE