More safety for users of fiber-coupled high-performance lasers

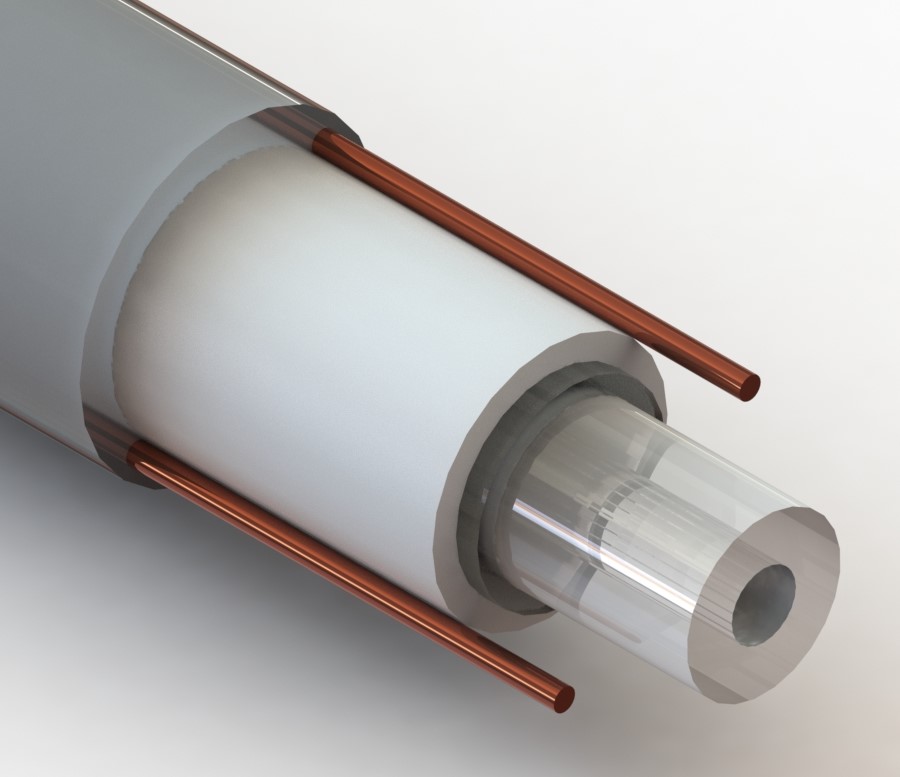

A new fiber design from CeramOptec increases user safety in connection with fiber-coupled high-performance lasers. Copper wire conductors in a polyamide jacket support the configuration of active protective devices that interrupt the laser circuit in the event of fiber breakage or connection problems and protect the user from leaking radiation. The concept can be applied to all standardized CeramOptec glass fibers.

CeramOptec enhances the safety for users of fiber-coupled high-performance lasers. Safety glass fibers with electrical contacting now facilitate the creation of active protective devices that automatically switch off the laser in the event of fiber breakage or connection failures. To this end, the polyamide jacket of the CeramOptec safety fibers contains two extremely thin copper wire conductors that are integrated into the circuit of the laser system via the usual fiber couplings. In case of a fiber breakage these conductors are destroyed and the circuit is thereby interrupted; contact interruption also happens in the event of malfunctions in the interface area between the fiber and the beam source. Users of medical or industrial lasers are thus reliably protected against the emission of harmful laser radiation. Since the two copper wires are applied together with the polyamide sheathing after the fiber drawing process, the new fiber concept can be implemented for all standardized CeramOptec glass fibers. All-rounders such as the standard Optran© UV/WF fibers are also available as safety fibers, as are the solarization-free Optran© UVNSS special fibers or the homogenizing Optran© NCC fibers with polygonal core geometry. For optimum coverage of all bending radii and temperature zones, safety fibers are available with copper wire conductors of 50, 100 and 150 micrometers. Custom configurations are also available on request.