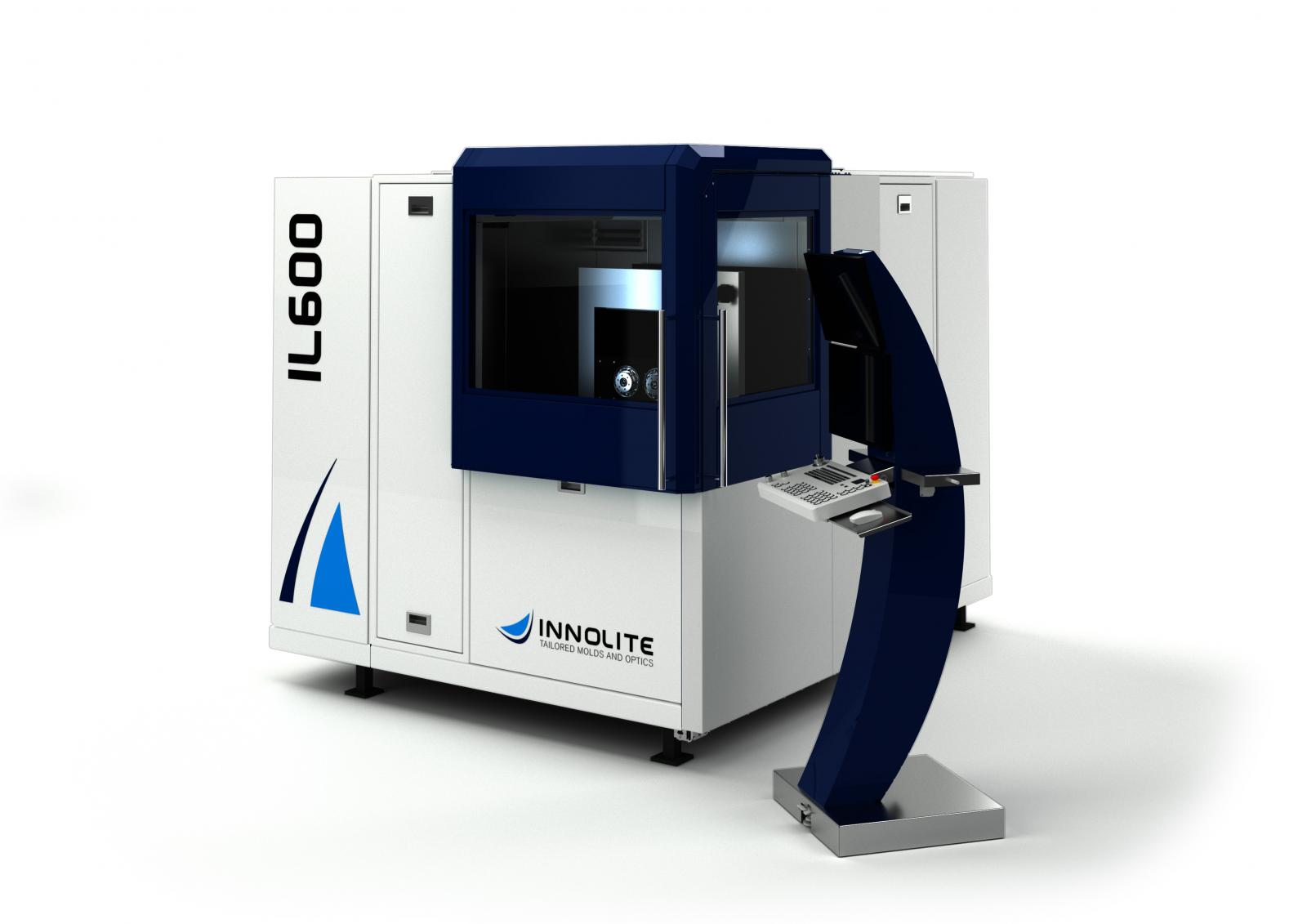

INNOLITE: IL600 UP Machining Center

»Driving Productivity in Ultra Precision Technology«

is the main focus for the Innolite GmbH, while serving customers in generating optical surface finishes for the past 12 years. Both as an optics manufacturer and supplier of ultra precision machining centers we are active for the optical industry. In addition, our activities in the development of machines, process technology and metrology lead to a broad range of expertise. As a result, Innolite GmbH introduces their latest product development: The IL600, a 4-6

axes ultra precision machining center.

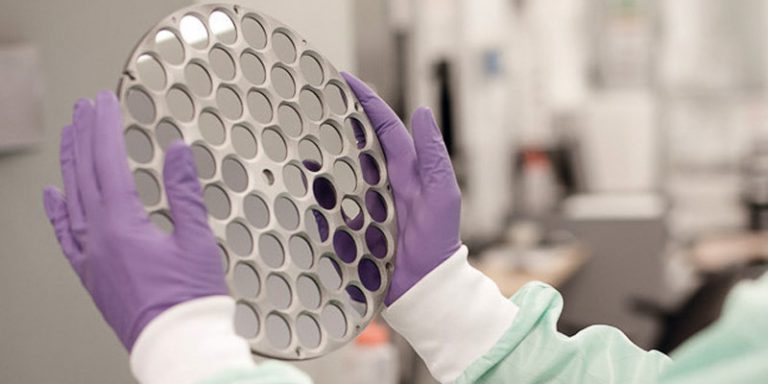

The compact design of the IL600 combines machining – as turning, ruling, milling, grinding – and measuring of

components with a diameter of max. 600 mm. Form Accuracy (PV) < 0.1 μm and roughness (Ra) < 1 nm are

achievable manufacturing qualities. An integrated circulating air shower serves not only as a filtration system but also as an air conditioning unit, with a temperature constancy of < 0.1 °C. The core of the IL600 is an innovative control system: ILCAM DIRECT DRIVE 3D. With 10,000-50,000 pts / sec, this software offers ultra fast setpoint processing for freeform and microstructure manufacturing. The offline axis interpolation increases the interpolation points by a factor of 5 to 25 compared to the conventional online CNC control and can be used for higher processing speed or higher resolution. In addition, the NanoGrip zero clamping system enables a modular design by precisely exchanging both tools and workpieces with a repeatability of < 0.5 μm. The flexible application of modules increases both productivity and precision.

More information: